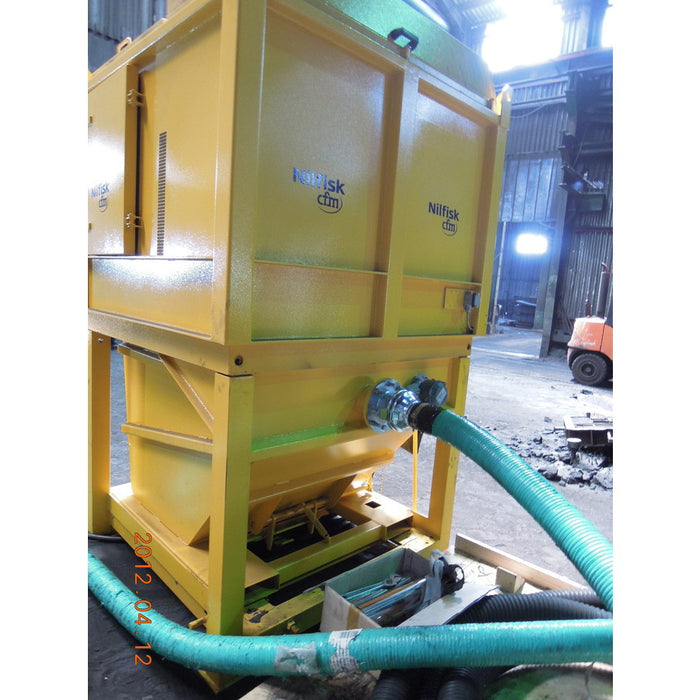

NilfiskCFM Spirovac Heavy Industrial Vacuum System For Illustration Of General Idea

Style: SPIROVAC

NilfiskCFM Spirovac Vacuum Systems For Industry

Brochure Click HERE

The CFM Spirovac system of vacuum units by Sibilia are available in various forms. The Compact version, with it's own recovery container, which can either be moved around by forklifts and cranes, or in the case of the Mobile version, they may be mounted on trolleys, or even on trucks, where they are energised with a rugged 3 phase diesel-electric power-plants.

Manufactured from sturdy steel plate, with built in sound-proofing, these units are available in versions powered by 3 phase induction motors from 22 kW to 37 kW in the Compact and Mobile formations, or up to 100kW in a fixed installation configuration. Therefore a very robust power supply must be available.

The Compact is a very useful version for the Western Australian resources projects, as well as elsewhere around Australia to pick up very large quantities of material and moved very easily around a resource project.

For different applications, choose from the following Spirovac formations, a hopper discharge system, or the Big Bag system for the retention and easy transportation of large quantities of powder or granular material.

The discharge configuration allows it to discharge the material, into bags, rail or road trucks. Sometimes, simultaneously with its collection.

For a tailored method of working, the Spirovac can be connected to a fixed piping network, say in a mine or manufacturing plant.

For some configurations, a suitable Spirovac vacuum unit, is connected to a pre-separator. The collection unit for the sucked materials and powders is supplied with a heavy steel quadrangular constructed dump-door, so it can be emptied during the functioning of the machine. Or evacuated through a hose connected to the pre-separator or to the fixed piping network.

High grade cyclonic separation systems detains the majority of recovered material and hence passes to the suction unit only a small amount of the finer material. A level sensor arrests the vacuum operation, when the maximum level has been reached.

Transportable pre-separators can be moved to the discharge area by fork-lifter or crane.

In fixed installations, choose either the Big Bag frame, or manual or continuous discharge valves. Designed to effectuate continual discharge of the collected material in the hopper, it allows discharge of the material simultaneously with its collection by the Spirovac unit.

Depending on the product style and it's specific requirements, this arrangement's composed of two motorised 250mm spherical valves (SFC-C 250), or butterfly valves (F-C 250) that work in an alternating fashion driven and regulated by a microprocessor.

Please Note: No Plug Is Included.

As this item is a total engineering solution please Contact Us it cannot be purchased through the website.